Do or Dye Custom Fabric

Gang Sheet Builder- Direct To Film Transfers

Gang Sheet Builder- Direct To Film Transfers

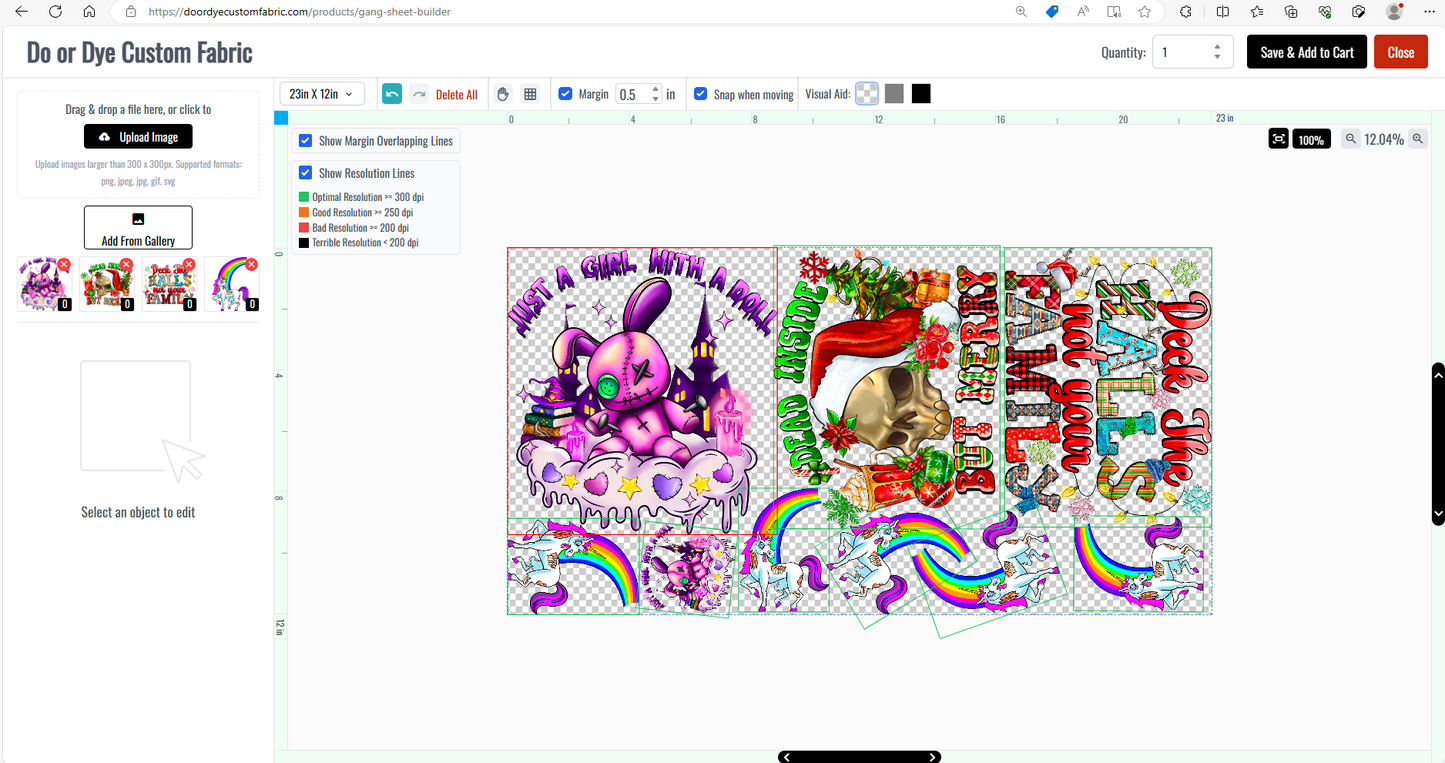

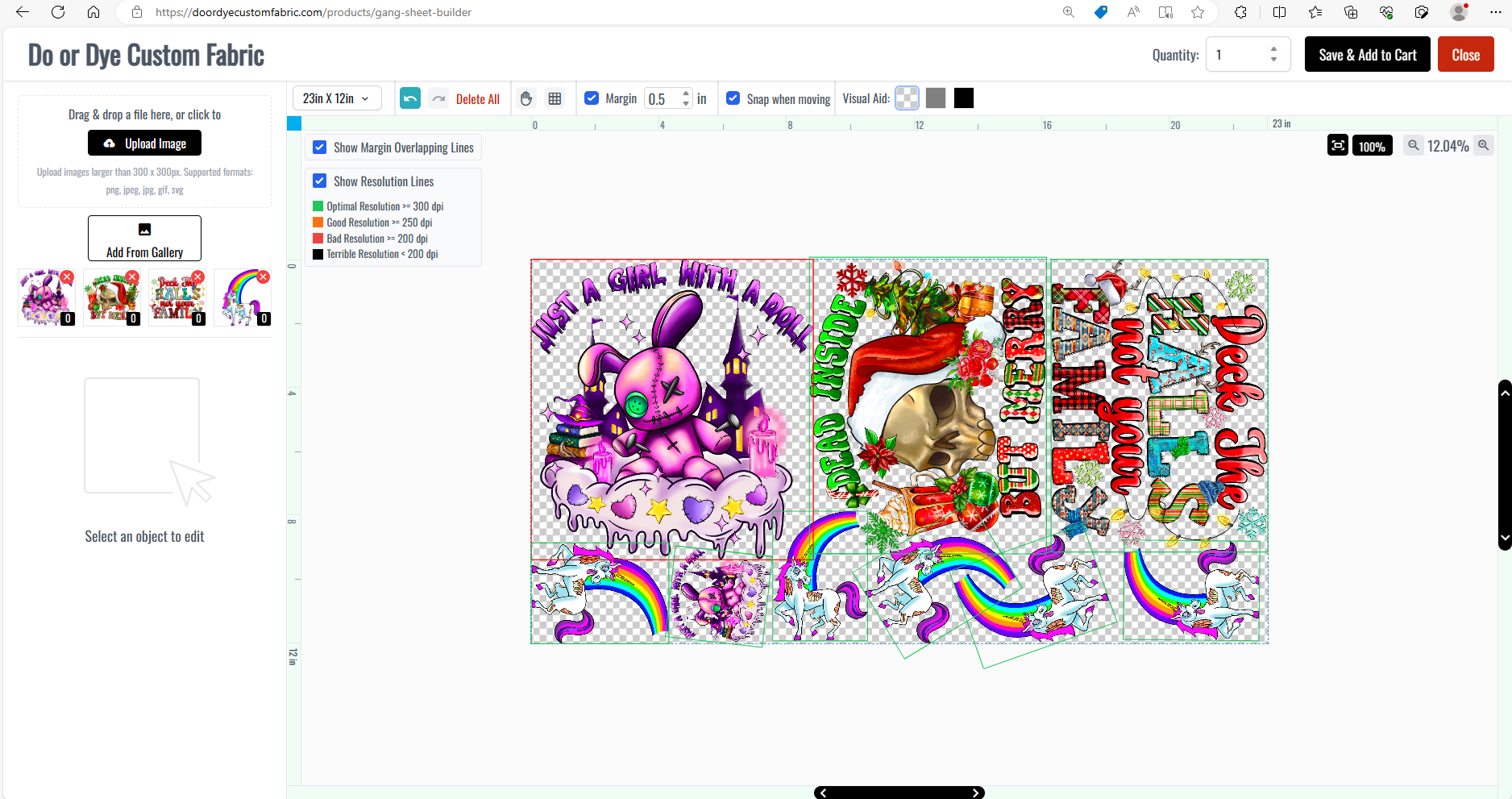

PLEASE PAY CLOSE ATTENTION TO YOUR IMAGES WHILE USING THIS LISTING!! The size that your image opens on the gang sheet builder is your files organic scale. Upscaling your image WILL cause the quality to degrade. Blurry images and white halos have a likelihood of occurring on low quality files. If you need help with your files, please reach out to us at Doordyecustomfabric@gmail.com prior to checking out with this listing. We do provide vectorization and art build services for an additional cost. Files are printed as they are output. No additional edits or corrections will be made to print files.

Direct to film transfers have taken over custom industry and we are here to help you and your business not get left behind! Our transfers are printed with a commercial printer using the highest quality print heads available. All of our supplies and materials are top rated for the industry and Oeko-Tex certified.

Please make sure that all images loaded to the gang sheet builder are high quality images, 300ppi preferred. We hold no responsibility for pixelated and or blurry images due to low quality art. If you need help with the gang sheet builder, please feel free reach out to us.

If you are unsure which size transfer you need, please check out our transfer sizing chart. You can find the chart here.

Direct To Film Transfer Instructions

- Prepress the material that you will be applying the transfer to for 10 seconds. Moisture within the material can result in adverse effects to your transfer. Prepressing helps to remove any moisture that may be within the fibers of the material.

- Once material is no longer hot to the touch, place the transfer on your material with the white side of the transfer facing down.

- Double check placement. Once transfer receives heat and is attached to your material, it cannot be moved or removed.

- Press at 300-320 degrees for 15 seconds with around 60lbs of pressure. If your press does not read out pressure, that's ok! Lean into your heating device and use your body weight to apply pressure.

- Wait until transfer has cooled down (1-2 minutes if allowing to cool naturally) and lightly peel the film away from the material. If transfer isn't easily releasing, repress for 8 seconds.

- Once film has been removed place a piece of white protection paper over the transfer and do once last press for 5-8 seconds. For this step you can use copy paper, parchment paper, butcher paper, Teflon sheet, tissue paper or a piece of white polyester fabric. If you live in a humid area you may want to use a thin piece of polyester as it can help to pull trapped moisture from the transfer.

You do not need a fancy commercial press to use DTF! A regular iron will work but please be mindful of uneven heating or scorching.

When submitting files for printing you are agreeing that 100% color accuracy isn't guaranteed due to not being possible. Many files are created in an RGB format while printers print in a CMYK format. Not just our DTF printers but ALL DTF printers. RGB has a much wider color wider color gamut than CMYK. As an example, the screen you're looking at now can produce over 16 million colors and that's on the lower end depending on your device. Although we run the highest quality print heads on the market that does not play a role in the color. All CMYK printers are limited to around 16,000 colors. What that means is, there is a wide range of hues that cannot be replicated from RGB to CMYK. We do our best with the use of color bridges and color spectrometer for fine details, but we ask that you take this into account before submitting any files for printing. Most of the colors that cannot be replicated with CMYK are on the lighter end of the RGB color model and also includes neon's. At DoD we have the added ability to print neon colors due to an additional print head on our equipment, but those colors are used for spot color and cannot be mixed to extend the CMYK color gamut. If you would like to take advantage of the florescent ink options, please visit the florescent ink DTF listing. If you have any questions or concerns and would like to talk to us prior to submitting, please select the 'chat with us' feature on the home page or by sending an email to Doordyecustomfabric@gmail.com.

By submitting files to DoD you are agreeing that you are the rightful owner of all submitted artworks. Should stolen artwork be sent to Do or Dye with claims of ownership there will be a 50% processing fee deducted from the cancelled and refunded order.

Stay up to date with all the amazing things happening at Do Or Dye by joining us on Facebook (3) Do or Dye Custom Fabric Inc. | Facebook.

Share